So, can you powder coat plastic? A form of coating called a powder coating applied as a dry, free-flowing powder is often applied electrostatically and then heated or exposed to ultraviolet radiation to harden, as opposed to traditional fluid paint, which is applied using an evaporating solvent.

Thermoplastic or thermoset polymers could make up the granules, typically employed to produce a hard finish that is more durable than ordinary paint. Metals like those found in household items, autos, bicycle frames, aluminum castings, drum equipment, and other objects are typically coated with powder.

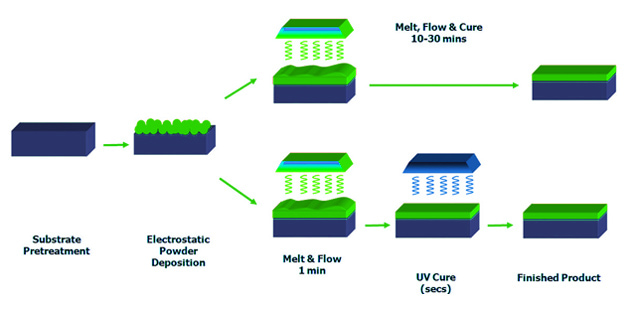

Additional materials, including plastics, composites, and MDF (medium-density fiberboard), can now be powder coated, thanks to advancements in powder coating technology such as UV curable powder coatings. In addition, it demands less warmth and furnace dwell time to treat these parts.

Powder coating may provide objects with a vibrant yet strong finish that is weatherproof, waterproof, and even damage-proof. The most popular material for powder coating is metal, but you can also do it with some plastics, polymers, glass, some types of powder coat wood, and MDF. Not all materials, nevertheless, can be powder coated. Find out what you can’t powder coat by reading on.

History and General Uses

Daniel Gustin created the powder coating method approximately around 1945, and in that year, he was granted US Patent 2538562. We coat an item using electrostatics in this technique, and the coating is then heated to cure it. The finish is more durable and robust than regular paint. The method works well for layers on the metal used in a variety of home devices, aluminum goods, and automobile components.

Does Powder Coat Stick To Plastic?

You can powder coat plastic material, of course!

You can finish numerous types of plastics using UV-cured powder coating because of the low temperatures, rapid melt rate, and use of conductive priming.

Properties of powder coating

Powder coating lacks a fluid carrier; therefore, it can generate layers that are thicker than traditional liquid coatings without flowing or drooping, and it produces few visual changes between surfaces that are covered horizontally and those coated vertically.

Few volatile organic chemicals are released during the coating process because no carrier fluid evaporates (VOC). Therefore, to achieve color blending and bleed special effects in a single layer, one can apply various powder colors before they are all cured collectively.

Applying smooth thin films is more complex than applying thick coatings that dry to a flawless, texture-free covering. Due to the powder’s glass transition temperature and particle size, the texture of the film gets increasingly orange-peeled as the film thickness is decreased.

Can You Powder Coat Plastic Chrome?

The process of electroplating a thin layer of chromium onto a metal object is known as chrome plating (less frequently referred to as chromium plating). Chrome is the name of the chrome plating byproduct. In addition to being attractive, the chromed layer can offer resistance to corrosion, maintenance simplicity, or increased surface stiffness.

Many individuals make the error of believing that they can only apply a chrome finish to metal components. However, it is possible to offer a plastic item the same gloss as a traditional chrome part by chrome coating it.

People frequently use the method of powder coating to coat components of all varieties and shield them from rust and corrosion. By spraying a dry powder onto a metal surface and then baking it until it hardens into a protective layer, the procedure entails coating the metal surface.

Although it is frequently utilized in the automobile industry (particularly with motorbikes), many people wonder if chrome can be powder coated. After all, chrome is a very slippery material, and the spray-on powder does need something it can adhere to; however, chrome items can be powder coated.

If you’re thinking of getting chrome parts powder coated, bear the following in mind:

- Most importantly, you must understand that chrome cannot be powder coated. The chrome won’t allow the powder coating to adhere. You must remove the chrome finish from the items before applying the powder coating throughout to complete the task effectively.

- After application, it is feasible to employ a powder coating that resembles chrome. Although it isn’t chrome, this kind of coating typically dries with a shiny surface that resembles chrome.

Can You Powder Coat ABS Plastic?

Acrylonitrile butadiene styrene, also known as ABS, is a popular thermoplastic polymer that is frequently utilized in injection molding applications. This engineering plastic is well-liked because it is inexpensive to produce and is simple for plastic makers to machine. Even more, the ABS material’s desirable qualities are not compromised by its inherent advantages of cost and machinabilities: Exceptional high and low-temperature efficiency, chemical inertness, structural strength & rigidity, and damage tolerance.

ABS plastic acquires these physical characteristics during the actual production process.

To understand more about the physical, mechanical, electrical, and thermal properties of ABS, view a complete ABS Material Data Sheet.

The only need is that the plastic substrate can endure 250°F to melt the powder coating onto the surface before UV curing. However, you should continue looking at powder coatings if your material can resist 250°F without melting. The melting point of ABS plastics is roughly 200°C (392°F); therefore, you can powder coat ABS Plastic.

Can You Powder Coat Plastic Center Caps?

The center caps use plastic with a weak metal layer covering them. You can take that off and spray a silver finish or a comparable finish on the plastic. How much you polish them after painting them and before putting on the lacquer(a liquid composed of synthetic materials, alcohol-dissolved shellac, or both that dries to produce a tough protective layer) will affect how shiny they are!

Some plastic center caps can be powder coated, but not all of them. For example, place one in your oven, heat it to 200 F, then keep raising the temperature by 25 ° at a time to reach the temperature at which your powder will harden. Again, see if it holds up. You’re okay to go if it doesn’t dissolve into a lump.

If at all feasible, use a low-cure-temp powder or cure at a lower temperature for a more extended period. For their powders, PBTP (Polybutylene terephthalate Plastics) may provide you with tables for extended cure periods at lower temperatures. For the powder to adhere, you must first heat it.

Can You Powder Coat Plastic Grille?

Many aspects are taken into account while making a vehicle notably remarkable when it comes to differentiating features. For example, you can identify a car by its color, body style, wheels, or other features, all of which have different traits. The grille just so happens to be one of those things. For example, you find the frequently grate-like metal or plastic structure on the front of every car and truck. But given that the grille serves a valuable purpose, why are some even made of plastic?

Grilles are much more than simply a stylish screen in a car; they are a very crucial part of it. They shield the engine compartment and, occasionally, the lights from mud, gravel, bulky particles, and other foreign objects that could harm the car’s components. In addition, it permits air to circulate through and cool the components. One must construct it using a material that can endure repeated abuse from the elements. Plastic is an excellent material for that.

A plastic grill cannot genuinely be “powder coated.” For the powder to adhere to the item, it needs a metal that can conduct electricity. It is just cooked on after that. A better choice might be to paint.

Additionally, you must bake the grille at over 400 degrees for powder coating. Go for it if you believe your grille can survive that temperature.

Can You Powder Coat ATV Plastic?

The fairings affixed to an all-terrain vehicle, or ATV, are referred to as “ATV plastic.” The fairings are parts that are mounted onto the car frame and composed of plastic or other composite materials like Kevlar®. They improve aerodynamics, beauty, and advanced engine shielding. The type of ATV for which the plastic is intended, as well as the rider’s choices for aesthetics and utility, can have a considerable impact on the size, shape, color, and design of the plastic used in ATVs. The plastics on an ATV are some of the most frequently broken parts of all the features.

While the price of ATV plastic is often pretty reasonable, the fairing components may charge more if they are sizable or have sophisticated designs. For instance, some ATVs equips headlights, trailers, or other extras; therefore, the plastics are made to suit them. More significant plastic components, like very wide hoods, might also cost significantly more than smaller fairings. For example, utility ATVs typically have bigger plastics for better coverage and protection, while racing ATVs usually have much smaller plastic components to keep the weight of the vehicle low.

Generally, people paint ATV plastics compared to powder coats. To paint, First of all, you’ll need to clean, sand, and then eliminate particles from the plastic that hinder paint from adhering. Then, to seal and protect the paint job, use a conductive primer, color, and top coat after you’ve completed that.

How to Powder Coat Plastic?

With UV-cured powder coatings, we can successfully coat a variety of plastic types and grades.

Plastics Powder Coating with UV Cure

An electrostatically applied coating material is UV-cured powder coating. The component is electrostatically ionized and momentarily warmed during the finishing process. Since most plastics won’t conduct electricity and will distort when heated, it is often painted with liquid paint and let to air dry.

UV-cured powder coating only needs 130°C for 1-2 minutes to melt the powder before being instantaneously cured by UV light energy. The exterior of the element is made conductive by applying a primer. You can finish numerous types of plastics using UV-cured powder coating due to the general low temperatures, quick melt period, and use of conductive priming.

Final Words

The ability of a specific object to endure the heat required to complete the task is maybe the most crucial factor to take into account when powder coating items. However, the majority of materials are unable to withstand the extreme heat needed for powder coating.

For these reasons, if you want a powder-coated product, it is simply preferable to use metal. However, it would help if you were sure that any parts you present for powder coating were produced of a metal that can withstand the extremely high temperatures involved in the powder coating procedure.

Before sending your parts out to be powder coated, see if you can remove any rubber or plastic parts that are linked to them. In the end, there are no guarantees that these parts of your item will endure the powder coating procedure; if they melt or burn away, the part may be deemed unusable.